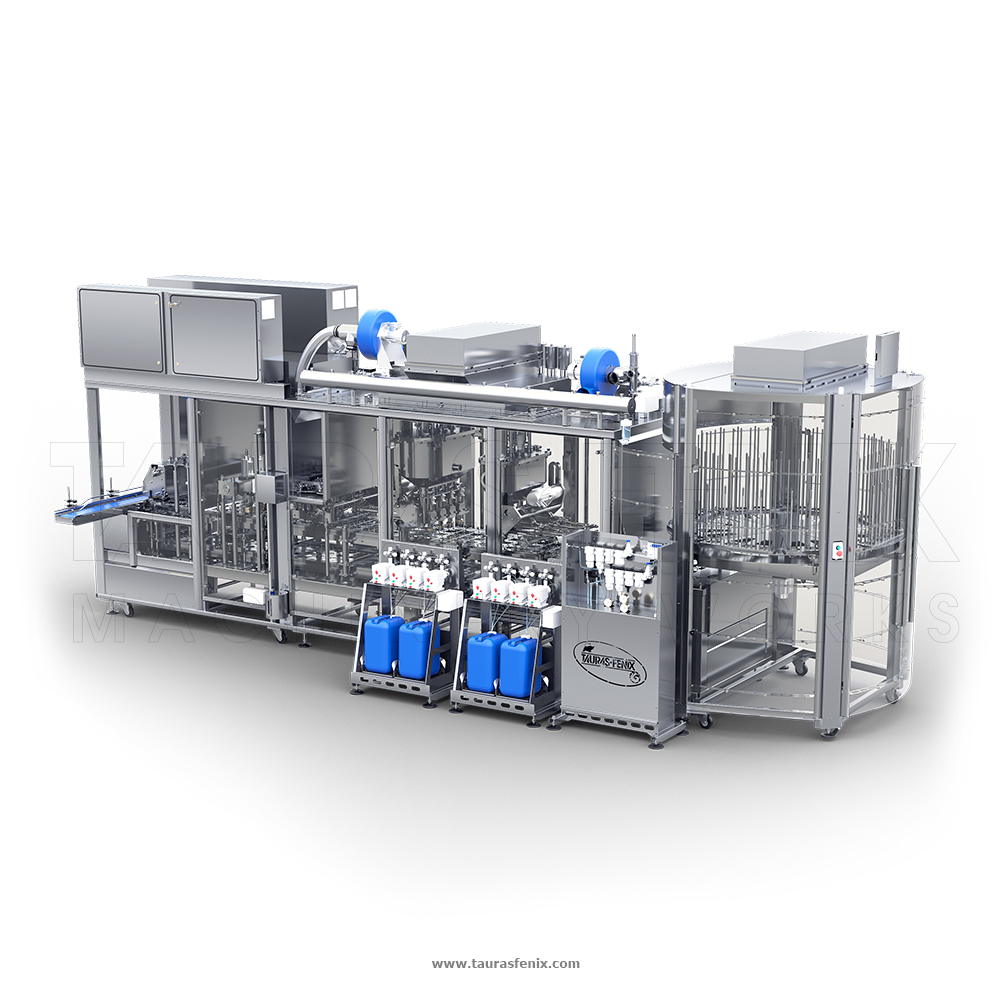

The multi-row automatic in-line machine PASTPACK 4L ULTRA CLEAN PRO is designed for dose filling liquid and pasty products containing soft, easy deformable additives of up to 10 mm in plastic cups with their further sealing with aluminum varnished foil and capping.

PASTPACK 4L ULTRA CLEAN PRO is a hardware equipment whose disinfection systems not only meet the requirements of hygiene class IV presented in the generally accepted VDMI classifier, but have also been modified by the manufacturer with consideration to all the requirements of customers that arise during operation.

Ultra Clean machine versions meet VDMA Hygiene Class IV:

- Hopper equipped with sterile air blowing system to save the microbiological parameters of the product

- Closed chamber at positions of containers disinfection, product filling, foil placing and sealing for protection from the external environment

- Feeding of sterile air into the chamber, purified from microorganisms and bacteria using HEPA-filters (Class H14)

- Chamber treatment with 30% hydrogen peroxide

- Containers and foil treatment with hydrogen peroxide steam with following drying by hot sterile air and ventilation

Linear Pastpak 4L boasts an increased level of hygiene backed up by antibacterial treatment of monocups and foil with a solution of hydrogen peroxide (H2O2) of up to 35% concentration.Containers and foil are processed in two stages.During the first stage, containers and foil are disinfected with the steam of hydrogen peroxide in a special chamber prior to packaging. Afterwards, they are treated with a stream of hot sterile air. Exhaust air with disinfectant residues is removed from the sterilization chamber and the working space through an exhaust probe.The temperature of the evaporator, the dose of hydrogen peroxide, and the temperature of drying the cups are managed from the touch control panel of the machine.

The device is completely sealed off by a protective chamber made of stainless steel with a boost of sterile air. It is also adapted for a CIP sink.

Products to be packed:

Milk, yoghurt, sour cream, cream; cottage cheese, cream cheese, curds;

butter, spreads; oils, sauces, mayo, mustard, ketchup, tomato paste;

salads with fraction under 15 mm, sea weed; pate, caviar; honey,

marmalade, jam, chocolate paste; small piece snacks, nuts, chips,

croutons, crackers, etc. Liquid and paste non-food products: chemicals,

liquid soap, washing fluids, etc.