Санкт-Петербург (Россия )?

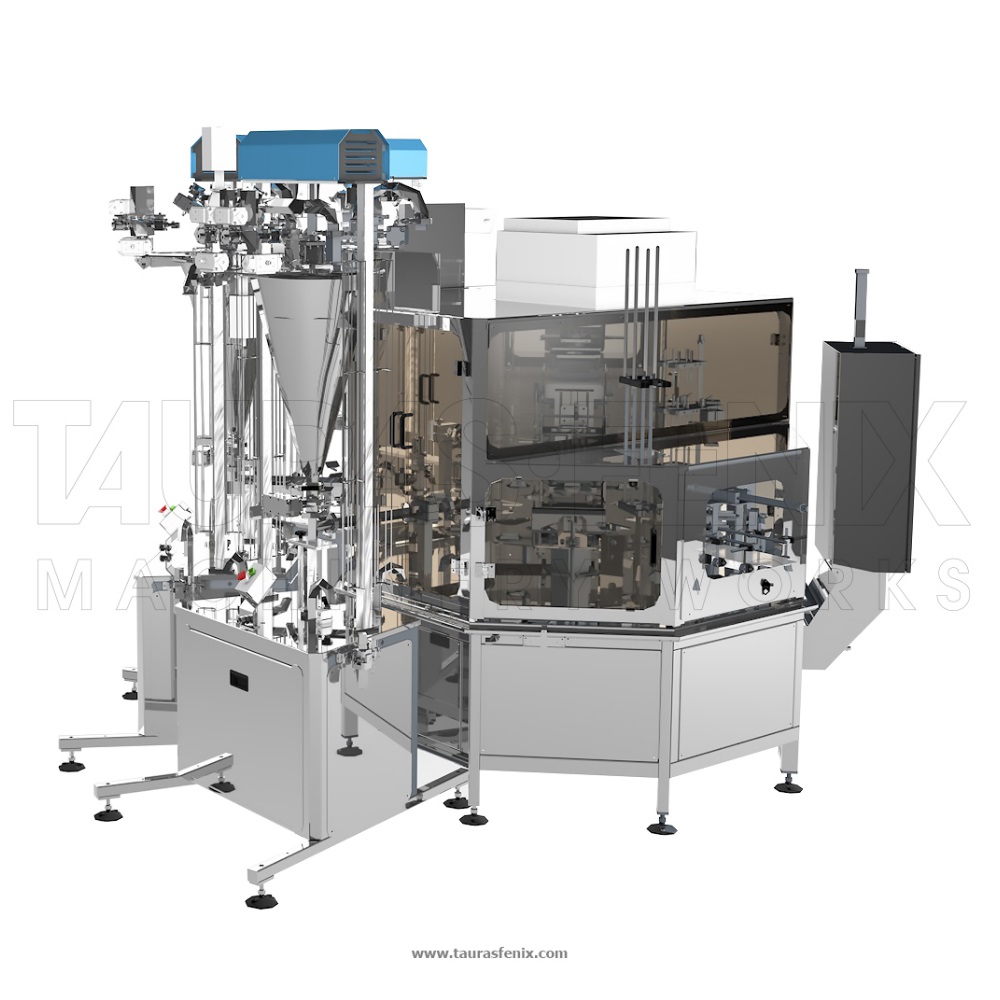

Order Pastpack R2/multicomponent product at favorable prices from the manufacturer «Tauras Fenix» – machine-building plant for the production of packaging equipment ☎ Call +7 (812) 443-51-29 or leave applications on the website ✔

Sour cream, cream, yogurt, dairy desserts, including stuffing; crumbly cottage cheese, granular cottage cheese with a cream topping, curd mass; mild cheese, curd cheese; butter, margarine, spreads; chocolate paste, jam, marmalade, honey; snacks, chips, rusks, nuts; sauces, mayonnaise, ketchup, mustard, tomato paste; pate, caviar, caviar butter, etc.

Йогурт

Творог

Сметана

Варенье, джем, повидло

Творожная масса

Плавленный сыр

Сливочное масло

Шоколадная паста

Чипсы

Сухарики

Орехи, сухофрукты

Майонез

Кетчуп

Горчица

Томатная паста

Паштеты

Икра

Пресервы