Is Your city

Санкт-Петербург (Россия )?

Санкт-Петербург (Россия )?

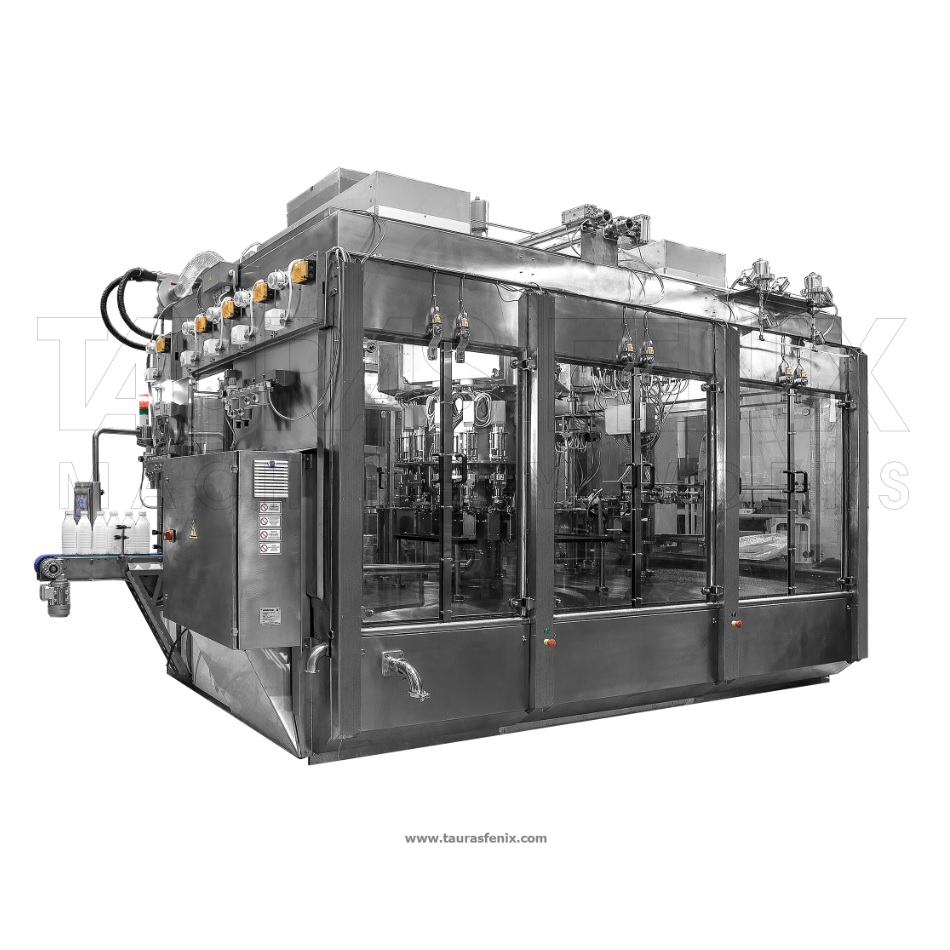

Liquid packing machine for filling into pet and glass bottles.

TRIBLOCK TF 6000 is an automatic machine which combines the following operations in sequential technological process:

TRIBLOCK TF 6000 is an automatic machine which combines the following operations in sequential technological process: