Санкт-Петербург (Россия )?

Санкт-Петербург (Россия )?

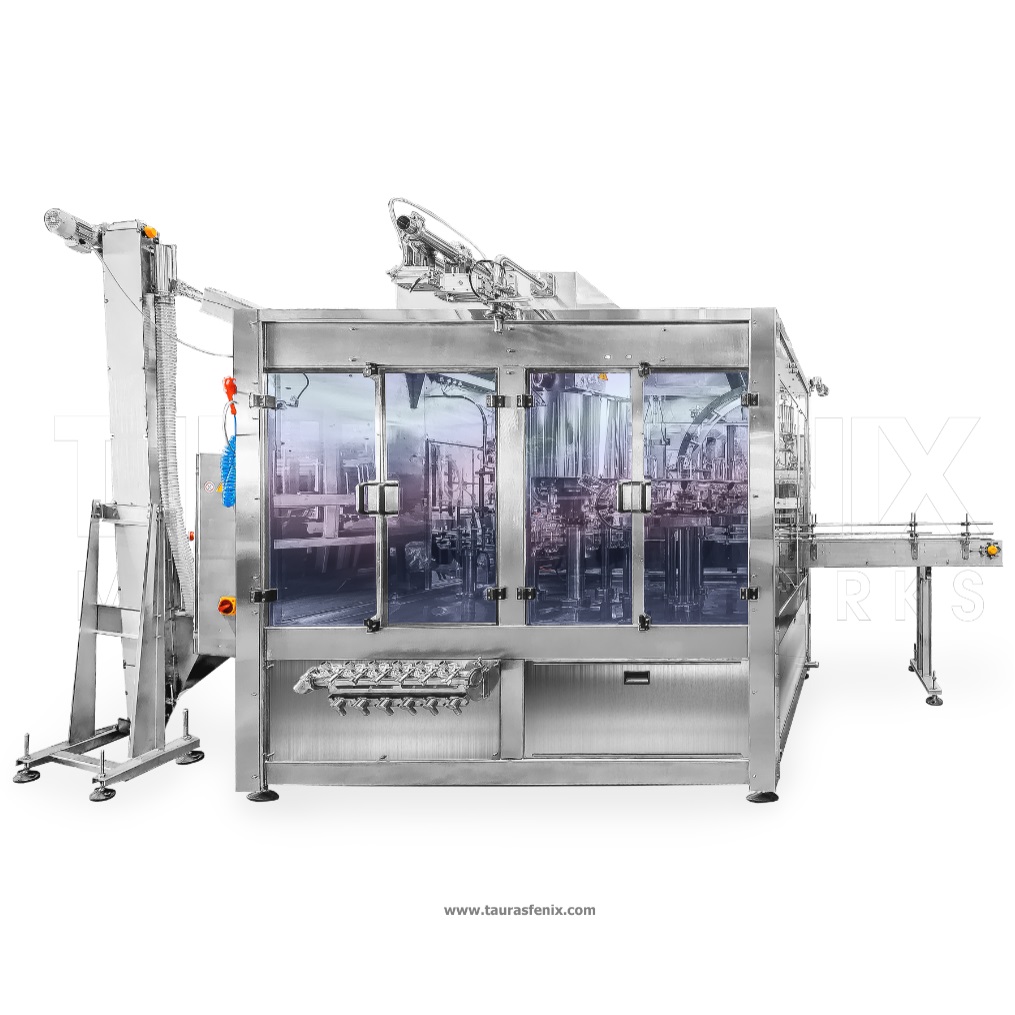

The machine is designed to automatic fill (weighing/volumetric) liquid and viscous dairy products into PET-bottles (hereafter referred to as bottle) and twisting them with plastic caps with guard collar.

The machine is designed to automatic fill (weighing/volumetric) liquid and viscous dairy products into PET-bottles (hereafter referred to as bottle) and twisting them with plastic caps with guard collar. Metal units and parts of the machine conta...

DetailsThe machine is designed to automatic fill (weighing/volumetric) liquid and viscous dairy products into PET-bottles (hereafter referred to as bottle) and twisting them with plastic caps with guard collar. Metal units and parts of the machine contact with food products are made of corrosion-resistant material permitted by the Russian Agency for Health and Consumer Rights.

The filling continuous operation machine is a monoblock which combines machines for sequential functions (3) of the technological process: