Packaging machines for powder&free flowing products

Packaging machines for liquid products

Horizontal packaging machines LINEPACK

Packaging Machines PASTPACK

Filling lines

Confectionery Equipment

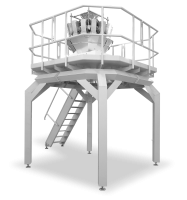

Dosing Systems

Shrink equipment

Secondary (transport) packaging

Stand Up Pouch Packaging Machines

Clipping devices

Gable Top Carton Fillers

Labeling machines

Glazed cheese bars production lines

Packaging Lines

Conveyors

Italian packaging machines

Specialty equipment